Almost there! Class participants (minus one student) show off their progress.

This spring LAMP has partnered with the University of North Florida to teach a class called The History of Shipbuilding. LAMP’s Sam Turner teaches the Tuesday lecture and Brendan Burke teaches a Thursday lab. In the class students are learning about vessel construction from the times of the ancient Phoenicians to our nuclear navy. On Thursdays the students meet in the lab and have been working to learn how to properly construct a ship’s half model. The process of learning how to build a half model is an invaluable part of learning how vessels are designed and how the complex lines of a boat interact with water, gravity, and motion. A secondary part of the class is learning to use some basic hand tools that require the user to go slowly and think about the pending accomplishment. As we are about to wrap up the class I thought I’d offer some commentary on how it has progressed.

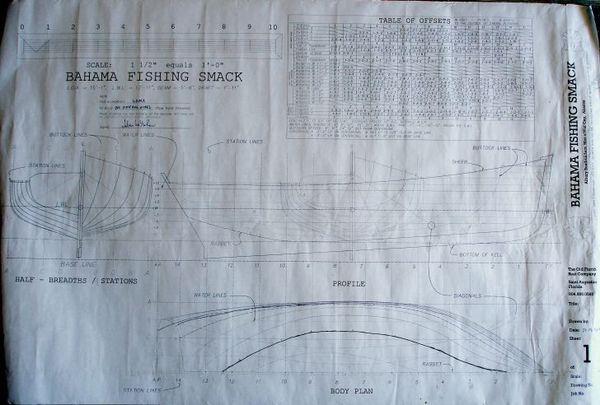

For the class, our half model is a Bahama fishing smack. The real boat is a design refined in the Abacos as a commercial fishing boat and the lines were drafted by John Lubbehusen, a master boatbuilder here in St. Augustine. In past years John, also known as ‘Bahama Jack’, spent quite a bit of time in the Abacos and studied wooden Bahamian fishing boats, ultimately taking the lines off of a historic boat that wound up in Cortez, Florida. This type of hull offers a good learning platform for students working on their first half-model. It has no hollow in its hind quarters and requires no special tools. The lines of the boat are also appealing and make for a nice finished product.

The lines as drawn by John Lubbehusen, a traditional wooden boatbuilder here in St. Augustine. Visit his webpage HERE.

The wood we used was a beautiful tight-grained red cypress. Donated to LAMP by Joe Woods, this sort of quality wood works well, has a nice appeal, and is getting very hard to find! I resawed the donated short planks into 3/8″ boards for the students. Each half model involves 13 pieces of wood that equal 6″ slices of the real hull. Trace the waterline lifts on the wood, cut each lift section out, glue them together, plane and sand it, varnish it and presto, a half model right?! Not so easy. Half models aren’t hard to make, but they take some time and understanding of tool use and how to interpret boat lines.

Its not easy to find wood this pretty any more. Red cypress.

Working in the lab, each student learned the steps to lay up their hulls and is now in the process of finishing the final fairing and shaping of the hull. It was a treat for each student to cut out the sheer and the transom from their glued-up lifts, it was that point that an awkward chunk of wood became a smooth, boat-like piece of art. Using templates students find the fairness of the hull at each station and, with careful planing, remove wood to reveal the proper shape of the boat.

At the end of the class each of the students will have learned how to go from a 2D set of plans to a 3D construct. They will also have good experience with some basic hand tools that, while largely overlooked in today’s construction industry, are the building blocks of woodworking and shipbuilding. Taking the time too, to build a half model allows the workman the time to learn from and appreciate the basics of a vessel’s hull and how a the smooth curves flow to make a functional and beautiful boat.

Only one more class to go, its all gone by so quickly! I hope the students have learned half as much as I, this has been a very rewarding experience. Most of the students are seniors and will graduate this summer, I have enjoyed working with each of them and wish them well.

Kevin Deady works with Bryan Dunbar to adjust a plane blade.

The guys at work. We converted a cement/concrete lab into an ersatz wood shop for this class.

More planing guys, more planing!

In order to learn what you know, try telling someone what you think you know! Before the class this is my rendition of the Bahama Fishing Smack. I modified the bow a little and you can see it does not conform exactly to the plans, an important difference to understand and know when trying to replicate something versus mimic it. Not sure how this would stack up to the real thing if built, but I like the lower bow a little more and a smoother transition to the stern.

Its amazing what a few coats of varnish will do!