Sitting at my desk about a week or so before Thanksgiving, I received a call from a gentleman who said he had a large anchor that had recently come from the sea. We get lots of calls and visits here at LAMP from folks who have found things on the beach and want to identify them, but few six-foot anchors. He said he had a picture and some information about the anchor and wanted to share it with us. I met with Richard, who told me a story….

Dredge Padre Island

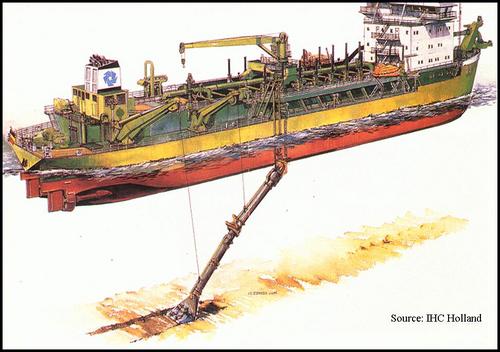

Lets take the focus off St. Augustine right now and head north to the St. Johns river. A heavily industrialized waterway, the St. Johns handles international shipping to supply the Port of Jacksonville. Cars, coal, fuel oils, containers full of computers, fruit, and sundry other goods flow in and out of the port every day. To handle modern shipping the main shipping channel is maintained to a depth of 40 feet, a task that requires constant monitoring and dredging. To keep the channel cut to the appropriate depth, the THSD Padre Island digs out shallow spots in the river and removing the spoil out to sea. The Padre Island is a trailing head suction dredge, see the picture below, which pumps up riverbottom into an inner hold. When full, the dredge lifts the suction head out of the water and steams out to a spoil dumping ground. Once on site, her bottom is forced open by hydraulic rams, to release the contents of her hold onto an approved spoil site. Click HERE for a video of how these things work, pretty interesting!

Trailing Head Suction Dredge, the suction head is what was being recovered from the sea floor when the anchor was snagged.

Early this past Fall, the Padre Island had reached her spoil dumping site, several miles out to sea, and began to offload. A cable failure on the suction head caused it to drop from its stowed position alonside the ship, and dangle to the ocean floor. Not able to retrieve it, the suction head had to be cut away from the ship and allowed to fall away. Marking the spot, the Padre Island returned to port and the salvage operation began. Great Lakes Dredge and Dock, the owners of the Padre Island contracted Mobro Marine Inc. to help with the recovery of their 85,000lb tool. A seagoing heavy lift barge was sent out to the site and divers attached cables for the lift. Once the suction head was on board the barge, it was towed back to Mayport to be reattached. During the tow, some of the cables from the suction head were dragging behind the barge while the crew was cleaning up the mess. When the two reached the Mayport jetties, they had to stop and finish cleaning up the broken cables. Using cranes to pull the cables back on board (think of tons of cables, some up to 2″ thick) the crew was unprepared to see a large anchor fouled in the mess of cable when it was finally all onboard. After unloading the sution head, the barge proceeded back to Green Cove Springs, where Mobro and Great Lakes both have repair and staging yards. It was as this point LAMP was contacted.

The Great Lakes Dredge and Dock repair/staging yard in Green Cove Springs.

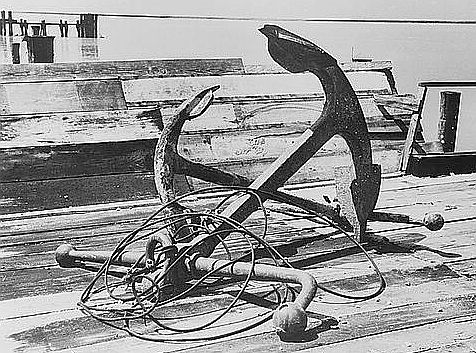

The anchor.

After telling me the story, Richard asked me if we might be interested in the anchor. I told him that accessioning an artifact such as a large anchor in need of conservation would require some serious consdieration and thought. While we have conservation tanks of all shapes and sizes, a 6′ by 6′ anchor was a little big for us and we don’t have the apparatus to handle it for cleaning and treating. However, the State of Florida does. A conversation began with the state to see if the anchor could be conserved in their laboratory in Tallahassee. After getting all of the details and arrangements in place, it was agreed that the anchor would be acessioned by the St. Augustine Lighthouse & Museum, to be conserved by the State of Florida Bureau of Archaeology, and returned to the Lighthouse Museum as an outside exhibit when its done.

As you can see, this anchor has been snagged before, note the cable corroded to one of the palms. The whole arm of the anchor is called the ‘fluke’ and the flat blade on the end is a ‘palm’.

LAMP Intern Brian McNamara inspecting the anchor prior to loading.

The process will take at least a year to remove salts and minerals from the metals (this anchor consists of wrought iron and cast iron) and then it will be coated with a solution to protect if from the elements.

To get the anchor from its temporary home in Green Cove Springs, the Lighthouse rented a truck last Tuesday morning. When Home Depot opened at 0700 I was waiting to get their rental truck. LAMP Intern Brian McNamara met me and we headed out to Green Cove Springs for our 1000 loading date. If you have never been to Green Cove’s industrial docks its quite a sight. Finger piers extending into the St. Johns river used to host over 600 ships in a ready reserve fleet, leftover from World War II. Brian and I pulled up to the Great Lakes Dredge and Dock yard. Huge piles of dredge pipe, giant mooring anchors, bollards, and other marine brick-a-brac were arranged in lines throughout several acres on the edge of the river. It was the first time I had seen an entire depot for rudders, propellors, anchor chain, pump bodies, cable winches laid out and ready to be shipped to a broken down dredge anywhere on the Atlantic or Gulf coasts. Behind one of the piles was our anchor. Normally this three-quarter ton piece of iron would seem large and imposing but the scale of things around us, and it, made it seem kind of puny! Nontheless, we were met by helpful yard staff who loaded the anchor onto our truck.

Green Cove Springs after WWII. While there are only a few ships there now, it still serves as an industrial maritime site.

Up she goes!

Easy there, slowly now!

The rental truck bed was slick aluminum and the last thing I wanted was to have almost a ton of iron bouncing merrily down I-10 at 70mph through traffic. Anchors are usually pretty good at stopping things and I didn’t want to see how effective it was on, say, a Honda. Brian and I were ready with load binder straps and when we were done, it looked like a spider had laid a web over the thing. I’m fairly sure the truck could have done a complete flip and and anchor would have still been there! After a quick final check of the load, Brian and I headed out for the main haul to Tallahassee. Driving west on I-10, we got quite a lot of looks from folks wondering why we were toting a big rusty anchor down the highway! Furthemore, when we arrived in the capitol, and drove right by the state capitol, more than a few lobbyists, legislators, and activists paused from texting, conversing, and sign waving to note our passing. Our final destination was the Florida Bureau of Archaelogical Research, located underneath the Florida Museum of History. After backing the truck into the loading bay, we met Claire Tindal, convervator for the bureau and our main point of contact. She was assisted by Paul Chamberlain and Eric Holdos, both archaeologists for BAR. They moved the overhead gantry lift into place and as soon as we unstrapped the anchor from the truck, it began a slow rise and rolled into their wet lab.

Strapped down, ready for the road.

Let’s go!

Its not every day that you have a whomping anchor in your rear view mirror.

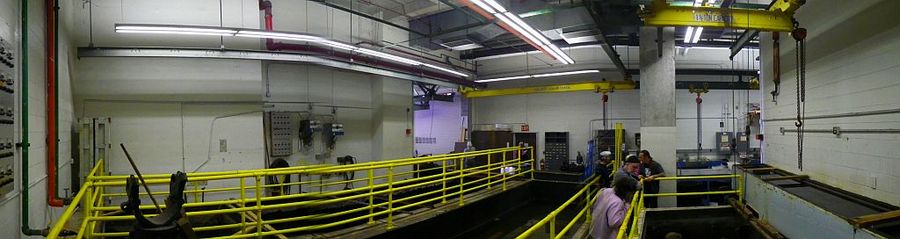

BAR’s wet lab is a little different than LAMP’s. For one, it is full of large concrete tanks used for artifact treatment and conservation. On the walls are banks of electrical distribution panels for electrolytic reduction and water taps for filling tanks. Overhead is a web of heavy i-beams for moving up to 1.5 tons anywhere in the lab and out to the loading dock area. Using this system, we rolled the anchor into the lab and lowered it into their deepest vat. After situating it in the vat we realized that it still stuck out a little! Claire and I discussed a few options, an ongoing project they will be working on to figure out and overcome. David Dickel, Collections and Conservation Specialist with BAR, joined us and as we turned on the water to fill the vat we ran over some options on how to fully conserve the anchor. At first, it will be soaked in fresh water to begin heavy desalination. Once chloride (salt) levels have lowered to a suitable level, electrolysis will begin to force out remaining contaminants, ultimately leaving an artifact ready to be dried out and treated to prevent further deterioration.

Unstrapped, ready to unload.

Overhead gantry systems are nice…

Repositioning for the final lift and travel into the lab. Eric Holdos and Paul Chamberlain are doing the move, both guys adroit at handling big artifacts. Thanks guys!

The wet lab at the Bureau of Archaeological Research, Tallahassee.

Resting in the vat, beginning to fill it. Its probably been a while since this thing has seen fresh water!

One of the flukes sticks out of the tank a little, a problem to be solved. Claire Tindal, BAR Conservator and Dave Dickel, BAR collections and conservation specialist are thinking this one over. One thought is to cut the stock (the big iron bar with the balls on the ends) temporarily for the anchor to be laid flat, conserved, and then welded back together after treatment is finished.

Late in the afternoon Brian and I hit the road to return to St. Augustine. It was a long day but a good day. In a year or so, we will repeat the operation but in reverse and bring the anchor here to the St. Augustine Lighthouse & Museum to go on exhibit. Who knows what stories this anchor can tell? Imagine the story of the Mattie Langdon, a three masted schooner of 303 tons burthen, lost at the mouth of the St. Johns in 1889. While being towed out to sea by a tug, a typical practice of the era for sailing ships, she struck the bar and Capt. Ross declared her a total loss at 4:00pm on September 6th.

Who knows what happened to the Mattie Langdon? Often, in shoal water salvage attempts were made, either to save cargo and/or the ship. Like St. Augustine, ships often had to wait to enter harbor due to contrary winds. Arriving at the mouth of the river, a ship might have to drop anchor to wait for favorable conditions or for a tug to arrive. Howling winds might cause a ship to part its cable or chain and leave an anchor behind, the main reason why ships carry more than on or two anchors. Shrimp trawls have ‘caught’ many of these anchors, as well as anchors that are part of wrecks, the front of many seafood restaurants attest to this. We look forward to setting up this anchor as an exhibit. While anchors don’t tell the whole maritime story, they are immediately recognizable and set the stage in people’s minds to begin the voyage of learning.

Many thanks to Great Lakes Dredge and Dock, Mobro Marine, and especially Richard, who made this happen! Also many thanks to the Bureau of Archaeological Research for conserving this artifact, especially to Claire Tindal, the anchor’s ‘mama’ for the next year or so. Stay tuned as we move this project forward, and others, to discover, preserve, and present the story of the Nation’s Oldest Port!

An underwater picture taken of a cannon undergoing treatment at the state lab.

I had to include this picture. Those big things behind me are impellers for dredge pumps. The pumps we use here at LAMP have impellers that you can hold in your hand, these babies are a bit bigger!!